A QUICK MENU

KirkpatrickPressure Lube Systems

|

|||||||||||||||||||||||

|

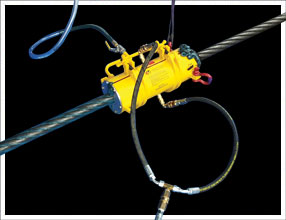

Kirkpatrick Wire Rope Lubrication Systems

| Kirkpatrick Wire Rope Lubrication Systems are excellent for Wire Rope and Cable Lubrication and Cleaning. In only one application, wire rope can have its surface and groove pattern scraped clean of product build-up and grit, while at the same time new lubricant is uniformly applied to the newly-cleaned surface. Coating product then fills any open spaces within the groove pattern, and internal strands open to receive it. |

Features & Benefits

| • | This is accomplished as the wire rope passes through a controlled, 100% pressurized, immersion within the Internal Seal Lubrication Chamber. |

| • | Surface moisture trapped within the internal strands is displaced and replaced with the newly applied wire rope coating product. |

| • | The Personal Safety benefit of utilizing the Kirkpatrick System is that it removes physical contact with the steel cable during the Lubrication process. |

| • | Health & safety improvements & highly effective process Military tested, coupled to life extension of the wire ropes themselves. MILSPEC NATO – use in US – Aust Navy for multiple years, these are simply the best things for the job |

| • | Essentially this is a system which forces lubricate, all the way through steel wired cables. This lubricates and protects the inside strands, as well as the outside strands. |

| • | Faster Treatment of the Steel Wire Rope |

| • | Full penetration of the Fluid Film to the centre of the Steel wire rope, so that the inner cores are also treated. |

Why Use Kirkpatrick Wire Rope Lubrication Systems?

| • | No Rubber seals to snap onto a rope, where fingers may be trapped. |

| • | No holding a heavy Lubrication Collar, whilst trying to align the rubbers with the Lubrication Collar. |

| • | Seal Sizes to match the rope being lubricated, ensuring a good seal and the best possible penetration of lubricant into the rope strands. |

| • | Seals fit into the Lubrication collar, and fit onto the rope at the same time the Collar is installed. No mucking around. |

| • | A discharge port is provided which allows some lubricant to exit the collar, taking water and other contaminates away with it. The lubricant must pass through the pressurised area before being able to drain off. |

| • | Light Weight Aluminum Collar, to reduce personal back loads. |

| • | Easy to secure Collar to rope. In most applications it can be placed on the rope and then balanced whilst tightening threads. |

| Kirkpatrick Wire Rope Lubrication Systems are designed so that in only one application wire rope can have its surface and grooves scraped clean of product build-up and grit while at the same time any new lubricant is uniformly applied to the newly cleaned surface and injected into the very core | |

| • | Moisture trapped in the internal strands is forced out and replaced with the new lubricant. |

| • | All systems are compatible with low as well as high viscosity lubricants |

| • | Groove Cleaners – Tough and Durable without being Brittle. Available in - Right Lay, - 6 Strand - Left Lay, - 6 Strand - Smooth Bore (for Non Spin Rope) |

| • | Full penetration of the Fluid Film to the centre of the Steel wire rope, so that the inner cores are also treated. |

|

|

||||||||||||

|

||||

You may also like:

|

|

||||

|

|||||